Deck Construction Guide

|

Building a deck seems to be as American as eating apple pie. While the general way a deck is built hasn't changed too much over the years, the details involved in the construction have.

The Code has very specific requirements for railings (guards), stairs and handrails, and very specific hardware is now required due to changes in the chemistry of treated lumber. The Chemistry Nearly 40 million lb. of arsenic was being used in this country every year, and most of it went into the pressure-treated wood used to build decks and playgrounds. But that all changed January 1, 2004. The Environmental Protection Agency (EPA) banned chromated copper arsenate (CCA) as a preservative for wood intended for residential use (except for the lumber that is used in permanent wood foundations). There's no need to panic about existing CCA-treated structures. The EPA says that they're fine. But if you're nervous about the chances of leaching chromium and arsenic, you can make your deck or swing set safer by coating it with an oil-based penetrating stain every couple of years. To make the new preservatives effective, their copper content has been boosted substantially -- from around 18% to 96% in some cases. Because ACQ and copper azole contain so much more copper, you can expect to pay from 15% to 35% more than you paid for CCA lumber. The cost varies because the amount of chemical treatment varies. CCA wasn't that expensive, so most CCA lumber was given a maximum dose of preservatives and rated for ground contact. To keep down the cost of the new pressure-treated wood, manufacturers will produce different levels of protection (chemical-retention levels) for different end uses. End-use categories will be marked on the tags stapled to the end of the board, but in general, they'll be determined by the dimension of the lumber itself. The lowest chemical-retention level will be for 5/4 stock, or decking. One level higher will be 2x lumber, or above ground. Ground contact will be 4x and 6x lumber, and other stock will be treated for permanent wood foundations (PWF, or structural members). The Footings Most decks are constructed with either ground contact treated lumber posts resting on concrete footings below the frostline or on concrete piers. If a deck is attached to the house the postholes must be 42-inches deep. If a deck is NOT attached to the house the postholes must be 42-inches deep OR all vertical supports must be crossed-braced. The depth of the postholes must be inspected by the Code Enforcement Officer prior to filling the holes. |

|

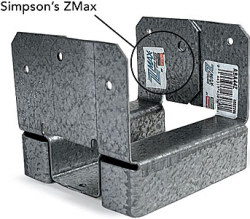

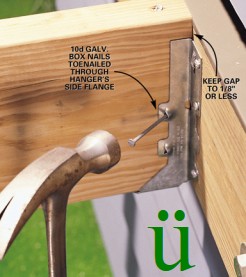

Joist hangers, post bases and all other hardware must be installed using approved fasteners. Approved fasteners typically include double hot-dipped galvanized10d and 12d common nails. Deck screws,

drywall screws and roofing nails are prohibited. The manufacturers agree: Never use galvanized deck screws or drywall screws to install joist hangers. Those screws don’t have the shank size and toughness to support joist loads. Install the largest hanger that fits the lumber. Never use a 2x6 hanger on a 2x10 joist. Avoid disaster by spending a couple of bucks more for the correct joist hanger. Hot-dipped galvanized bolts must always be used in beam and post assemblies. Deck screws are never acceptable for supporting the loads carried by beams. |

Unapproved screws are not allowed in joist hangers or other hardware.

Screws are not allowed in joist hangers and hangers must be tight against the sides of the joist.

For standard-type single joist hangers, use only 1-1/2 in. joist hanger nails for nailing into the side of the joist; for double hangers, use 8d or 10d nails. For double shear single hangers, fasten the hanger to the joists with longer 8d or 10d nails. This type of hanger requires fewer but longer nails for the side flanges. The nails penetrate into the wall ledger and therefore offer both better joist load capacity than standard-duty hangers and more protection against uplift forces caused by wind.

Screws are not allowed in joist hangers and hangers must be tight against the sides of the joist.

For standard-type single joist hangers, use only 1-1/2 in. joist hanger nails for nailing into the side of the joist; for double hangers, use 8d or 10d nails. For double shear single hangers, fasten the hanger to the joists with longer 8d or 10d nails. This type of hanger requires fewer but longer nails for the side flanges. The nails penetrate into the wall ledger and therefore offer both better joist load capacity than standard-duty hangers and more protection against uplift forces caused by wind.